According to the German Industry 4.0 Index, Industry 4.0 and the use of industrial Internet platforms have become a essential aspect for every other company. However, medium-sized companies, in particular, continue to insufficiently exploit the potential of these platforms. It is often dominated by individual solutions and simple technical exercises.

For the German Industry 4.0 Index, business consultancy Staufen together with experts from Staufen Digital Neonex surveyed around 450 industrial companies in Germany.

A great example of the unused possibilities of industrial platforms are web portals of many machine tool manufacturers, on which spare parts, additional parts and documentation are available. “All providers still have a very shielded portal that is limited to their own products,” says Dr. med. Jochen Schlick, Senior Partner at Staufen Digital Neonex. “However, this is not at all in line with customers’ reality, as they usually operate machines from various manufacturers and often have to use numerous platforms at once.”

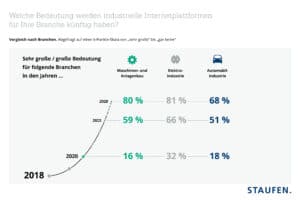

Small and medium-sized enterprises should therefore strive for manufacturer-independent platforms in order to ensure their own competitiveness. And the clock is ticking. According to the German Industry 4.0 Index, more than half of all industrial companies surveyed assume that platforms will have great to very great strategic importance for their own industry in less than five years.

“After initial experience with cloud and similar services, the time has now come for companies to critically examine their previous platform activities,” says Industry 4.0 expert Schlick. “The challenge now is to move beyond just using technical gadgets and turn platforms into a lucrative sales and service channel for the entire lifecycle of a product.”

In addition to a strategic shift towards more cooperation and targeted development of the service business, new technical developments cannot be ignored. “The next step for platforms is establishing a direct connection to the machines via the Internet of Things,” says Management Consultant Schlick. “This requires developing real-time functionalities that, thanks to a 5G network that is currently under way, are now no longer just gadgets, but real business opportunities.”

Save the date: NEXCON on February 28, 2019

NEXCON is an international, fully virtual congress on smart manufacturing. As part of the 15-hour live event, leading experts from well-known companies and institutions (including BASF, Daimler, Schaeffler Group and Fraunhofer IPA) will speak on current trends, developments and experiences in the fields of digital transformation, data analytics as well as augmented and virtual reality in an industrial field of application. In addition, established companies and innovative newcomers will be presenting themselves in the digital exhibition hall. The focus of NEXCON 2.0 is also on the combination of the German initiative “Industry 4.0” and the Chinese initiative “Made in China 2025.” Additional information on participants, exhibitors and partners can be found at: www.nexcon.digital

|

More Information: STAUFEN.AG Kathrin Negele

|

STAUFEN.DIGITAL NEONEX GmbH Maya Worm

|

Press: Thöring & Stuhr – Partnerschaft für Kommunikationsberatung Arne Stuhr

|

About Staufen Digital Neonex GmbH – www.staufen-neonex.de

Staufen Digital Neonex GmbH is a subsidiary of Staufen AG and provides consulting services to medium-sized producers as they undergo digital transformation. In addition to pragmatic digital strategies for small and medium-sized enterprises, topics relating to smart factory, data science and digitization of product ranges and business models are also part of the program. Those involved can count on Staufen Digital Neonex as a steadfast partner. Uncertainty and any mistrust are reduced through customized qualification programs. Even when it comes to smart factories, one thing holds true for Staufen: People make the difference.

About Staufen AG – www.staufen.ag

Inside every company there is an even better one. With this conviction, Staufen AG has been advising and qualifying companies and employees for more than 20 years. Markets are on the move – the competitive pressure is enormous. Staufen helps to quickly bring about the right changes, increase productivity, improve quality and increase innovative strength. With the appropriate strategies and methods, the international lean management consultancy ensures rapid and measurable success. In order to leverage the potential available in every company, Staufen consultants establish a lively and sustainable culture of change together with executives and employees. Staufen subsidiary Staufen Digital Neonex supports medium-sized industrial companies on their path to digital transformation. The Academy of Staufen AG also offers certified, practice-oriented training courses. Of the 13 international locations, more than 260 employees serve customers all over the world. In 2018, Staufen AG was recognized by “brand eins Wissen” as “Best Consultants” for the fifth year in a row. According to the renowned industry study “Hidden Champions 2018,” the consulting firm is Germany’s best lean management consultancy and was honored several times with the “Best of Consulting” award by the “Wirtschaftswoche” journal.